Static plate

There are various possibilities for constructing a static plate: steel strapping, OSB or shear connectors

We will gladly help you with static plate calculations. However, please clarify the following points beforehand:

- design

- horizontal loads to be assumed, such as wind, stabilisation and possibly earthquakes

- type and position of load applications

- position of possible load transfer points, such as walls etc., of the static plate in the floor plan

- bearings, such as sleepers etc., for integration into the concept of the static plate

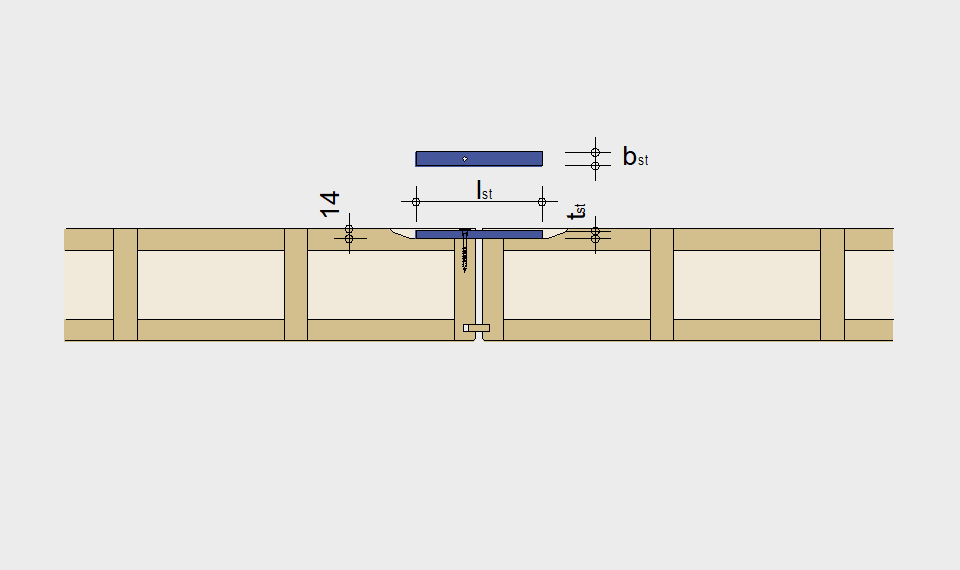

Shear connector

Shear connectors are used to form a static plate with LIGNATUR surface elements. They are also used to align the LIGNATUR elements.

The shear connector is inserted into the factory-prepared groove from above during installation. Fixing with a 6.0 x 60 mm pan head screw into the web serves to secure the position without a static function. The resulting offset torque is transferred via a pair of forces and introduced into the wood via contact. The force transmission therefore functions without constraint and the elements can swell and shrink freely. During installation, at least two shear connectors should be installed per joint before the next element is laid.

Verification with shear connector

Geometry shear connector with steel quality S235

bst: 20 mm

tst: 12 mm

lst: 180 mm

Static characteristics

Characteristic load-carrying capacity shear connector Fv,Rk = 10.19 kN

Shifting module Kser = 4.25 kN/mm

Distance between shear connectors ≥ 32cm

Structural design according to EN 1995-1-1

The modification factor kmod and the partial factor γM change depending on the relevant load case and load duration:

Wind = kmod 0.9; Earthquake = kmod 1.0

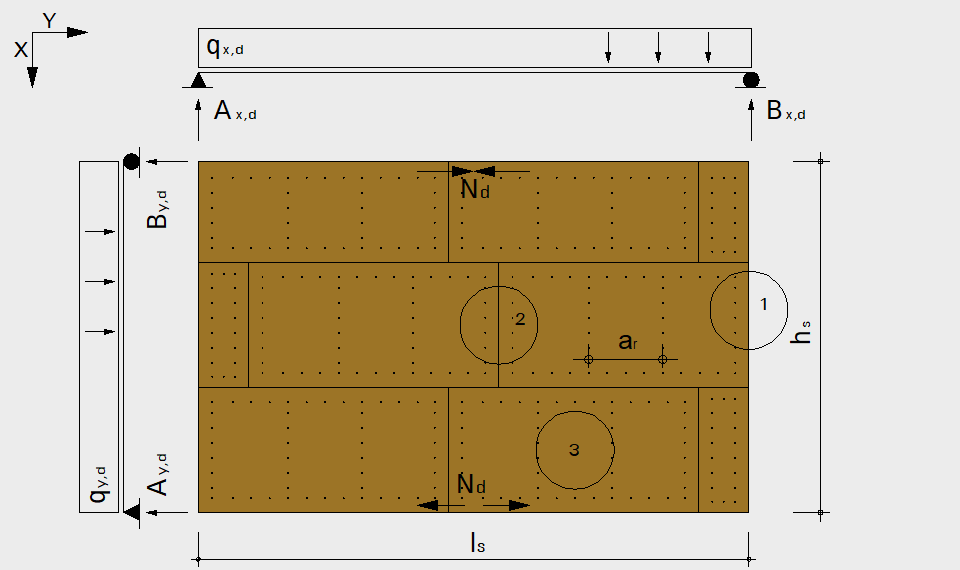

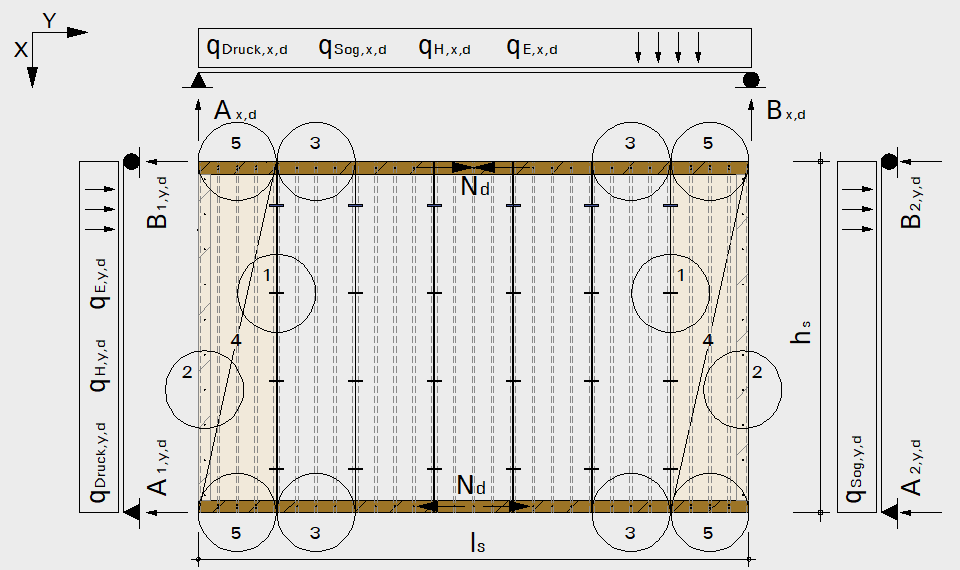

Static system and actions

Geometry:

Length of diaphragm: ls

Width of diaphragm: hs

Actions:

Wind pressure: qDruck,x,d respectively qDruck,y,d

Wind suction: qSog,x,d respectively qSog,y,d

Stabilisation load: qH,x,d respectively qH,y,d

Seismic action: qE,x,d respectively qE,y,d

Pertinent combination wind:

qx,d = qDruck,x,d + qSog,x,d + qH,x,d

qy,d = qDruck,y,d + qH,y,d

Pertinent combination earthquake:

qx,d = qE,x,d + qH,x,d

qy,d = qE,y,d / ls + qH,y,d

Maximum shear force:

Ax,d = Bx,d = qx,d * ls / 2

Ay,d = By,d = qy,d * hs / 2

Maximum moment:

Mz,d = qx,d * ls2 / 8

Maximum compressive / tensile force:

± Nd = Mz,d / hs

± Nd must be taken up by the supports. Joints must be designed with one and a half times the load-carrying capacity! The support reactions Ax,d, Bx,d, Ay,d and By,d must be transmittet through the primary construction.

1 Transfer of shear loads

Verification: Ax,d / FRd,tot ≤ 1.00

Ax,d Maximum shear force

FRd,tot Total design load-carrying capacity

FRd,tot = FRd * n

n Number of shear connectors

FRd Design load-carrying capacity per shear connector

FRd = FRk * kmod / γM

FRk Characteristic load-carrying capacity per shear connector = 10.19 kN

kmod Modification factor according to EN 1995-1-1 depending on the relevant load case or load duration

γM Partial factor

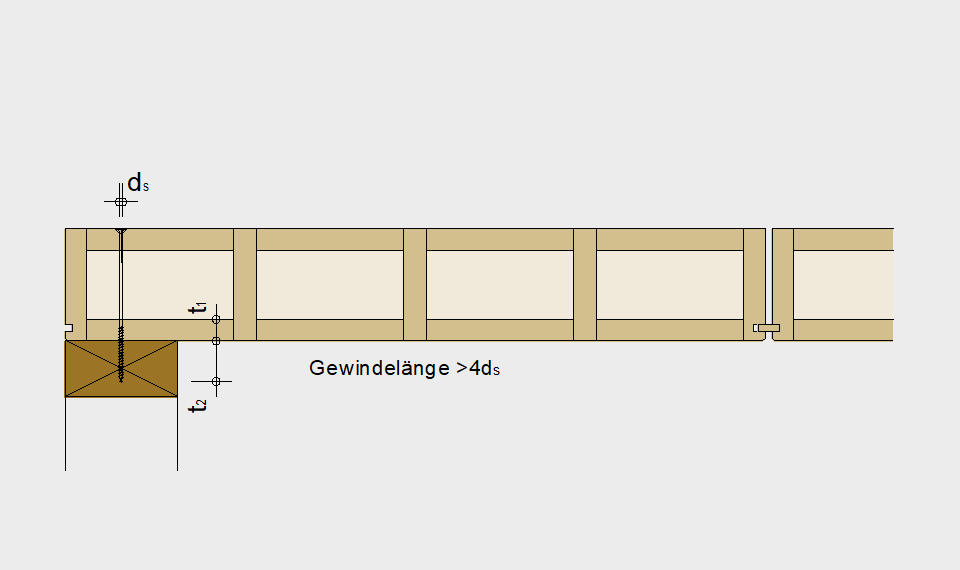

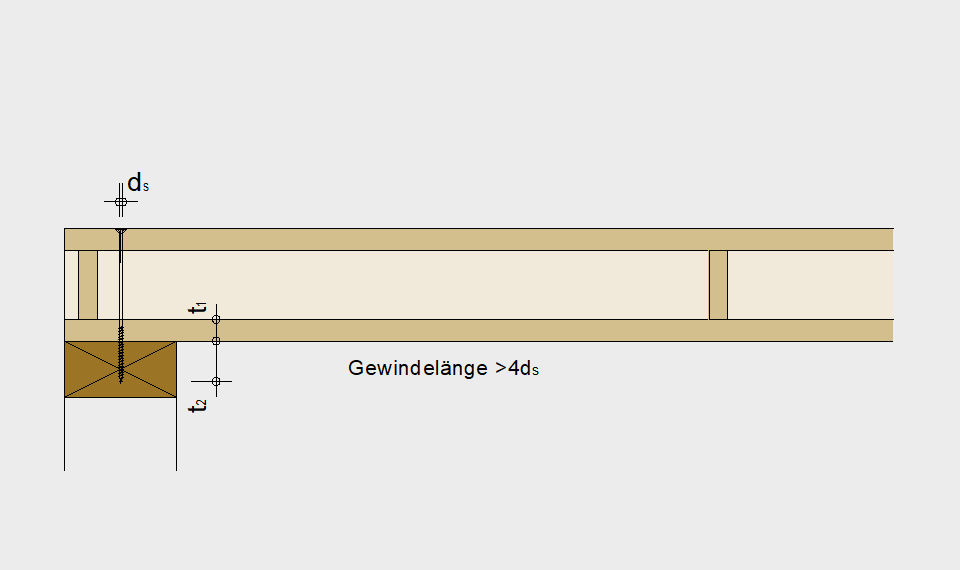

2 Connection to the supports

Verification: Ax,d / Fv,Rd,tot ≤ 1.00

Ax,d Maximum shear force

Fv,Rd,tot Total design load-carrying capacity

Fv,Rd,tot = Fv,Rd * n

n Number of screws per row, SPAX Senkkopf, screw diameter dS = 8 mm

Fv,Rd Design load-carrying capacity per screw

Fv,Rd = Fv,Rk * kmod / γM

Fv,Rk Characteristic load-carrying capacity per screw = 3.00 kN (pre-drilled)

at:

t1 Wood thickness (element) = 31 mm

t2 Penetration in the support = 40 mm

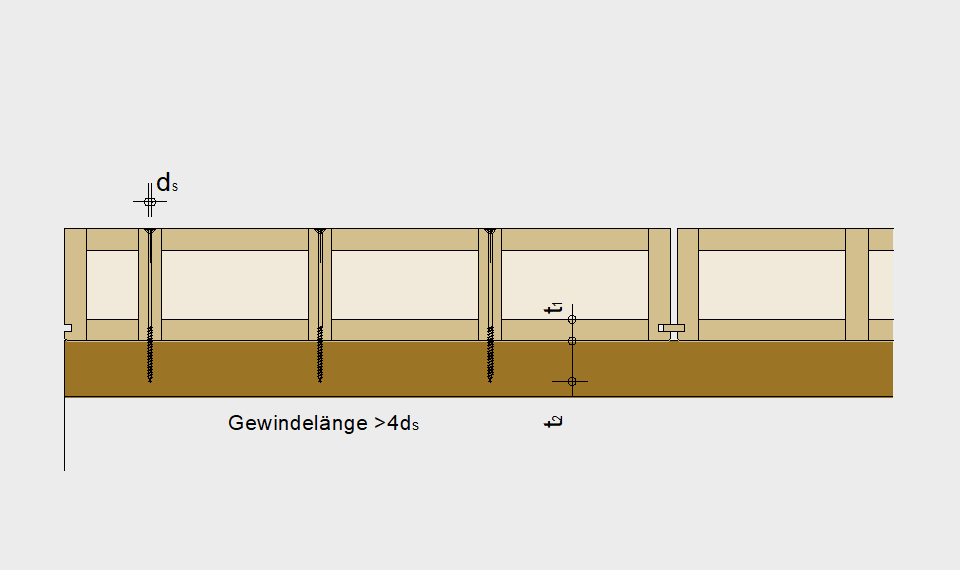

3 Connection parallel to the longitudinal wall

Verification: Ed / Fv,Rd,tot ≤ 1.00

Ed Maximum action parallel to the longitudinal wall

Fv,Rd,tot Total design load-carrying capacity

Ed = √(sw,v,d2 +qDruck,x,d2 ) / 1.00m

sw,v,d = Ax,d / hs

sw,v,d shear flow

qx,d Maximum shear force

Fv,Rd,tot = Fv,Rd * n

n Numbers of screws per row per m, SPAX Senkkopf, screw diameter dS = 8 mm

Fv,Rd Design load-carrying capacity per screw

Fv,Rd = Fv,Rk * kmod / γM

Fv,Rk Characteristic load-carrying capacity per screw = 3.00 kN (pre-drilled)

at:

t1 Wood thickness (element) = 31 mm

t2 Penetration in the support = 40 mm

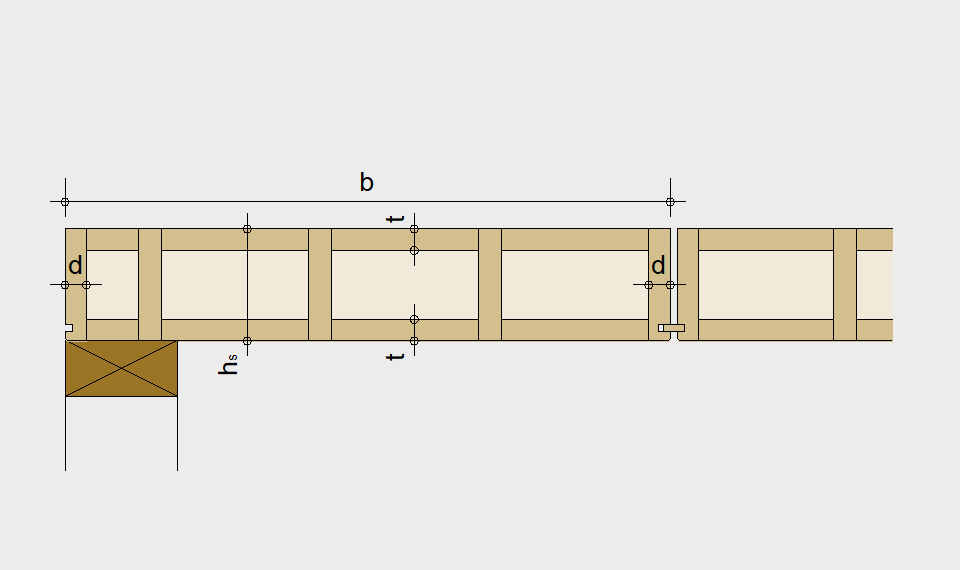

4 Verification of the load-carrying capacity

Verification: σm,d / fm,d ≤ 1.00

σm,d Maximum bending stress

fm,d Design bending strength

Verification: τd / fv,d ≤ 1.00

τd Maximum shear stress

fv,d Design shear strength

Maximum horizontal bending: wy ≥ hs / 1000

at:

b Element width

hs Element height

t Slat thickness

d Web thickness = 31 mm

5 Connection of border elements to the supports

Verification: Ay,d / Fv,Rd,tot ≤ 1.00

Ay,d Maximum shear force

Fv,Rd,tot Total design load-carrying capacity

Fv,Rd,tot = Fv,Rd * n

n Number of screws per row, SPAX Senkkopf, screw diameter dS = 8 mm

Fv,Rd Design load-carrying capacity per screw

Fv,Rd = Fv,Rk * kmod / γM

Fv,Rk Characteristic load-carrying capacity per screw = 3.00 kN (pre-drilled)

at:

t1 Wood thickness (element) = 31 mm

t2 Penetration in the support = 40 mm

Static plate

Dimensioning values

moment

Mz,d (qx,d) = qx,d . ls 2 / 8

tensile / compressive force

Zd = Nd = Mz,d / hs

shear force / bearing reaction

Ax,d = Bx,d = qx,d . ls / 2

Ay,d = By,d = qy,d . hs / 2

flow of shear forces

sv,0,d = Ax,d / hs

Verification

1 fasteners

fv,0,d = kv1 . Rd / av ≥ sv,0,d

2 shear strength OSB

fv,0,d = kv1 . kv2 . fv,d . t ≥ sv,0,d

3 shear buckling OSB

fv,0,d = kv1 . kv2 . fv,d . 35 . t² / ar ≥ sv,0,d

kv1 = 1.0 (boards are rigidly connected all around)

kv2 = 0.33 (one-sided sheating)

av = distance fasteners

t = 15 mm (thickness OSB)

ar = 800 mm (distance studs)

Rd,staple,Ø1.8 mm = 0.52 kN

kmod = 0.9

The floor bearings need to be dimensioned so that they can take the loads from Nd and Zd and transfer the reactions from the static plate. The design is performed according to EN 1995-1-1, section 9.2.3.