A tour of the company

Lignatur AG has been producing high-quality, load-bearing wooden floor and roof elements for more than 40 years.

Whether in new buildings or renovated old buildings, in single-family houses or multi-family houses, in schools, halls or offices: Many building owners throughout Europe are satisfied with their LIGNATUR floors, ceilings and roofs. LIGNATUR stands for innovative, modern and sustainable construction with the highest functional and aesthetic standards.

Location Switzerland

Lignatur AG is located in Appenzellerland, Switzerland. With 50 employees, we produce LIGNATUR floor and roof elements, advise our customers and continuously enhance and refine our wood construction system.

Wood as a resource

Careful handling of our raw material wood and our product is important to us.

Lignatur therefore only uses domestic wood from Austria, southern Germany and Switzerland. The wood comes from sustainably managed forests. After the delivery of the dried wood, it gets sorted.

Branch gluing

LIGNATUR floor and roof elements meet the highest demands. We take innovative paths to achieve this. One example is automatic branch gluing by a machine which was co-developed by us and which is used for the first time at Lignatur AG: it scans the wood for healthy knots on the later visible sides and fixes them.

Quality controls

Strict quality controls safeguard our entire production process. Electrodes measure the moisture content of the wood. Ongoing climate measurements and air humidification systems ensure a uniform room climate.

Our employees tag wood defects by hand. The cross-cut saw cuts them away.

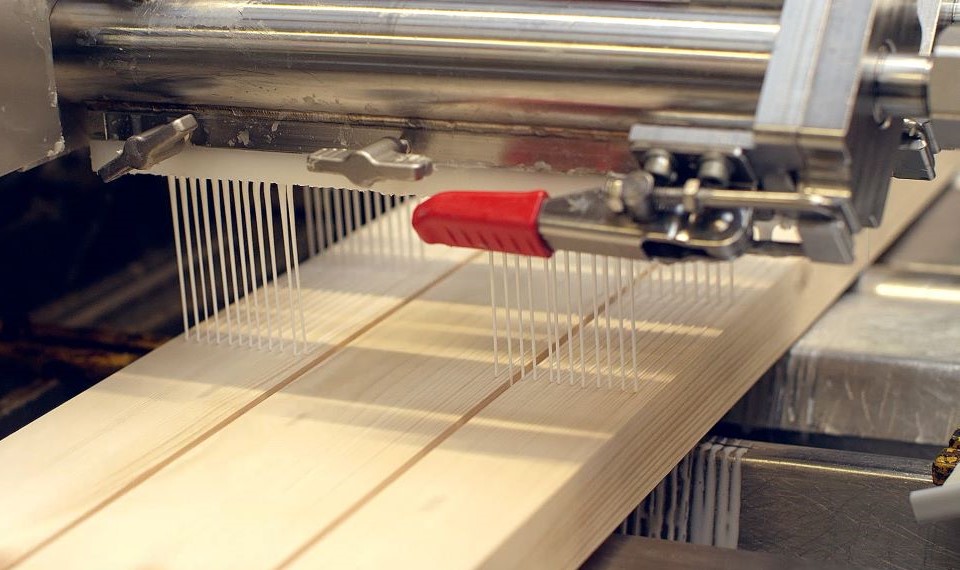

Finger-jointing system

The finger-jointing machine joins the individual lamellas, which are yet of unequal length, to form an endless lamella. It is then cut to the required length.

External monitoring

The high quality of LIGNAUR elements is monitored internally and externally. On a daily basis our quality manager cuts out hardened finger joints. He inspects some of them himself and passes the others on to external monitoring.

Next, the lamellas are given smooth surfaces in the planing machine. This is an important prerequisite for clean, visible gluing.

The plotter then labels the lamella with the date and property class C24 in accordance with Eurocode 5.

Glue application station

The hardener and glue are now applied. Cameras help our employees to constantly monitor this process as it must meet strict standards.

With a European Technical Assessment, LIGNATUR elements offer planning security for all those involved in construction - throughout Europe. Lignatur issues a Declaration of Performance for each delivery, which also includes the names of the technical assessment body and the notified external inspection body.

Legeplatz

Bei der Lignatur AG wird industriell gefertigt und doch ist jedes Element ein Unikat. Am Legeplatz werden die Einzelteile manuell zusammengefügt.

Jede Decke besteht aus einem Kastensystem. Die Hohlräume zwischen den Stegen bleiben leer oder werden gefüllt – je nach Anforderung des einzelnen Bauprojektes an Statik, Feuerwiderstand, Schallschutz, Wärmedämmung und Raumakustik.

In diese Decke wird ein Absorber hinterlegt. Später wird die Sichtseite perforiert. Das schlussendlich tragende Akustikelement erhält so einen Feuerwiderstand von 60 Minuten. Damit darf in der Schweiz mehrgeschossig bis 30 Meter, also bis 10 Geschosse hoch gebaut werden. Das zeigt deutlich: sichtbarer Holzbau ist heute eine etablierte und sichere Bauweise.

Hochfrequenzpresse

Das LIGNATUR Holzbausystem überzeugt durch hervorragende statische Eigenschaften. Die tragenden Elemente sind bis zu 16 Meter lang und 1 Meter breit. Große Spannweiten sind damit stützenfrei möglich.

Hier presst die Hochfrequenzpresse die Elemente in Form. Der Leim erwärmt sich, verteilt sich optimal und härtet unter Druck aus. Täglich werden ausgehärtete Abschnitte entnommen – und intern und extern auf Abscheren geprüft.

Das Verleimen im Holzbau ist eine Technik mit mehr als 100 Jahren Erfahrung – und in etwa gleich alt wie die Stahlbetontechnik. Die Decke hat nun eine optimale Statik – also eine hohe Steifigkeit bei geringem Eigengewicht und minimaler Höhe.

Planing machine

Grooving, chamfering and the surface finishing are now effected via the four-side planing machine. LIGNATUR elements meet the eye with a homogeneous and aesthetic wood surface.

Surface checking

Despite the latest technologies, human judgment is required - so our employees check the wood surfaces and correct resin galls.

Surface treatment

With Lignatur, shell equals shell build-out as our ceilings have a finished visible side. This saves additional work steps on the construction site.

The majority of LIGNATUR elements remain natural. However, our employees can also apply moisture protection, UV light protection or glazes on request.

Abbund

Unsere CNC-gesteuerte Lignamatic bindet jetzt die Elemente massgenau ab.

Perforation

The CNC Lignamatic also mills splice joints, circular cut-outs or our various accoustic types` perforations just as precisely.

Lignatur AG is the only company to offer load-bearing wooden floors/roofs with acoustic performance whose fire resistance is regulated in the European Technical Assessment. Here, the acoustics type 1 dynamic design is created.

Packaging

The finished CE and PEFC certified elements are now carefully wrapped in stretch film.

Chargement

Les éléments finis, emballés et numérotés, sont maintenant chargés et envoyés sur des chantiers dans toute l'Europe.