FIRE SEALINGS

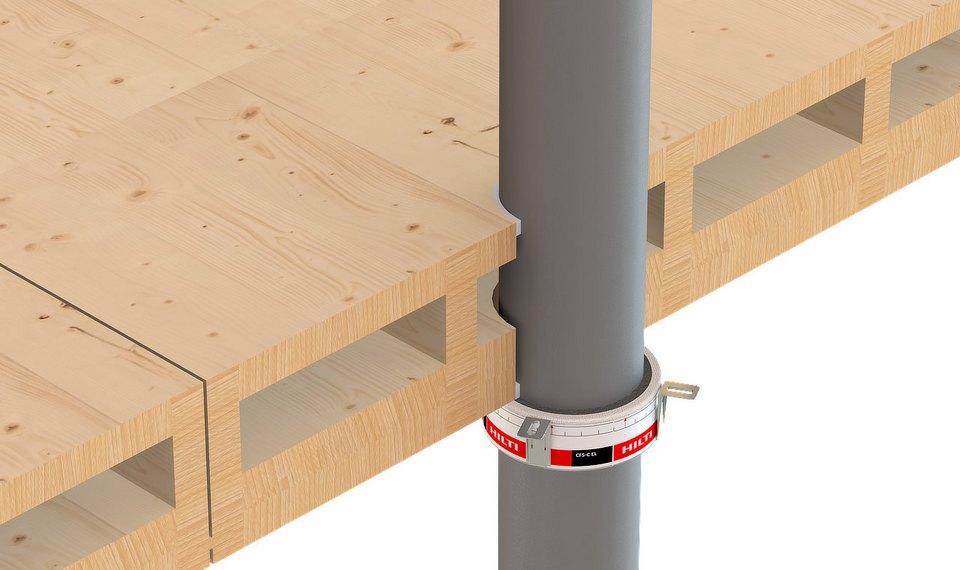

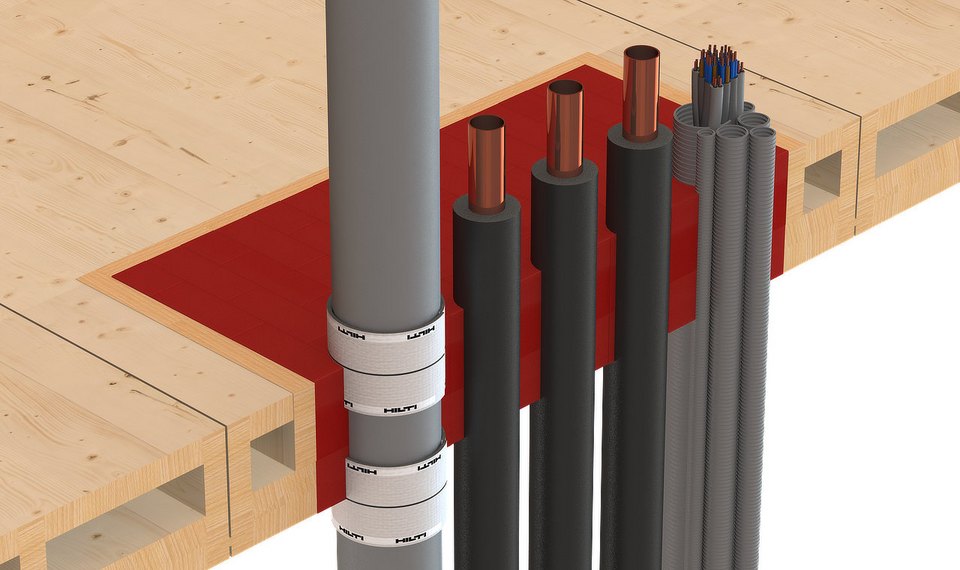

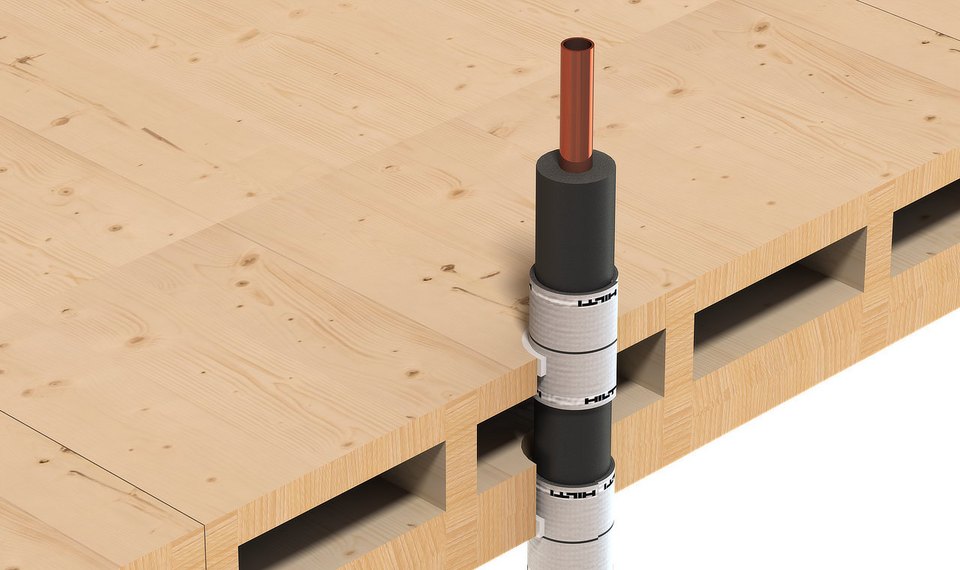

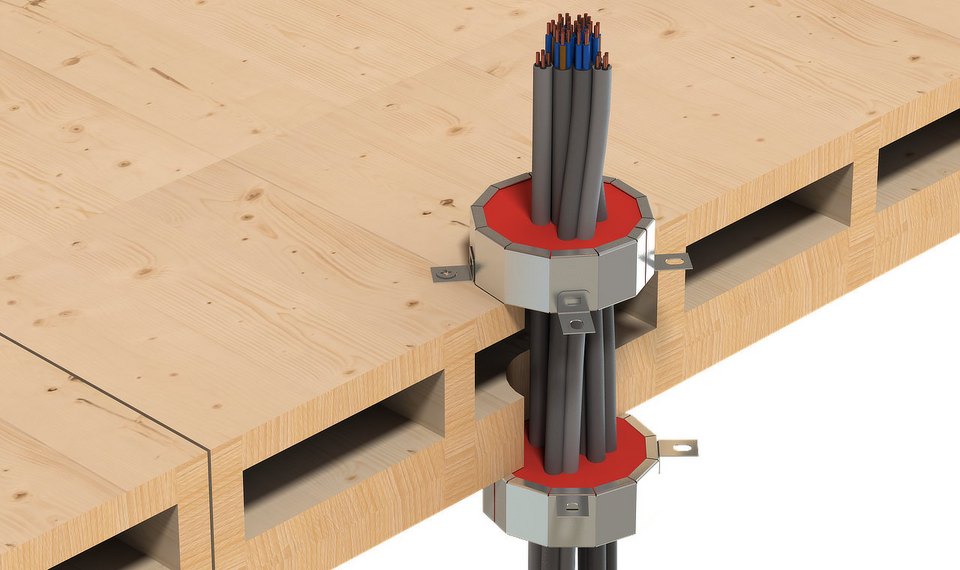

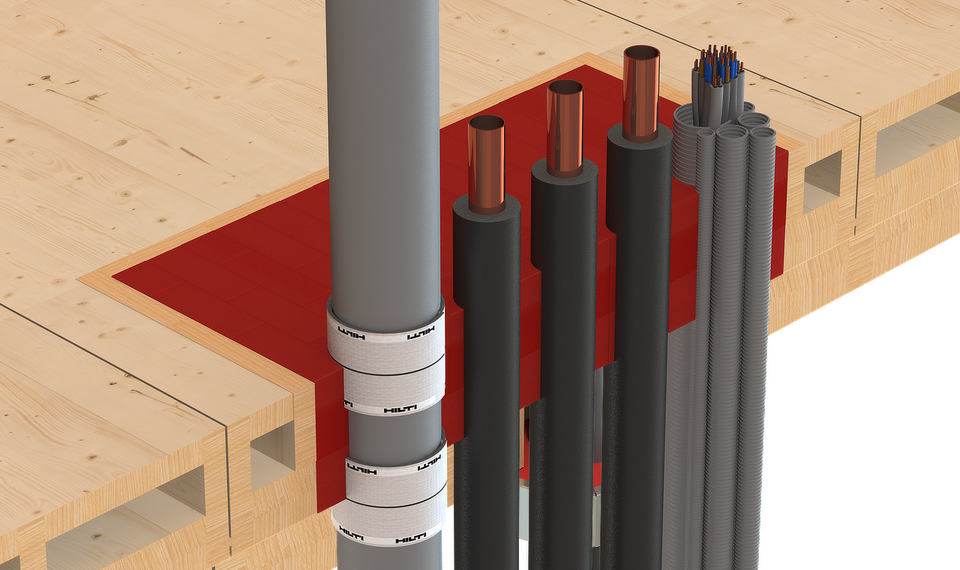

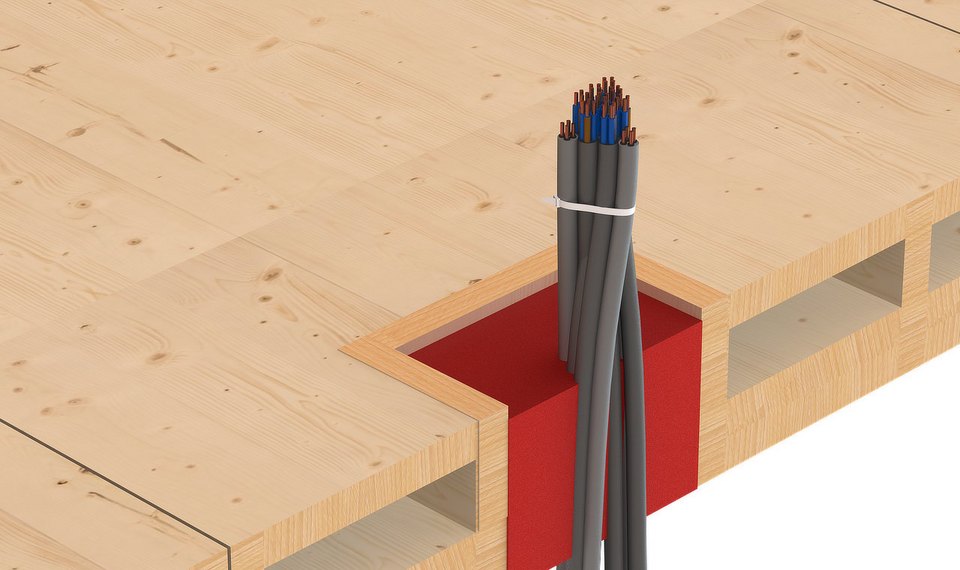

Firestop systems are installed at the supply and drainage lines that penetrate LIGNATUR ceiling elements to restore the fire resistance of the entire structural assembly. A wide range of tested and approved firestop systems is available for Europe, Germany, and Switzerland.

Sanitary (heating and drinking water)

Fire sealing systems put to the test

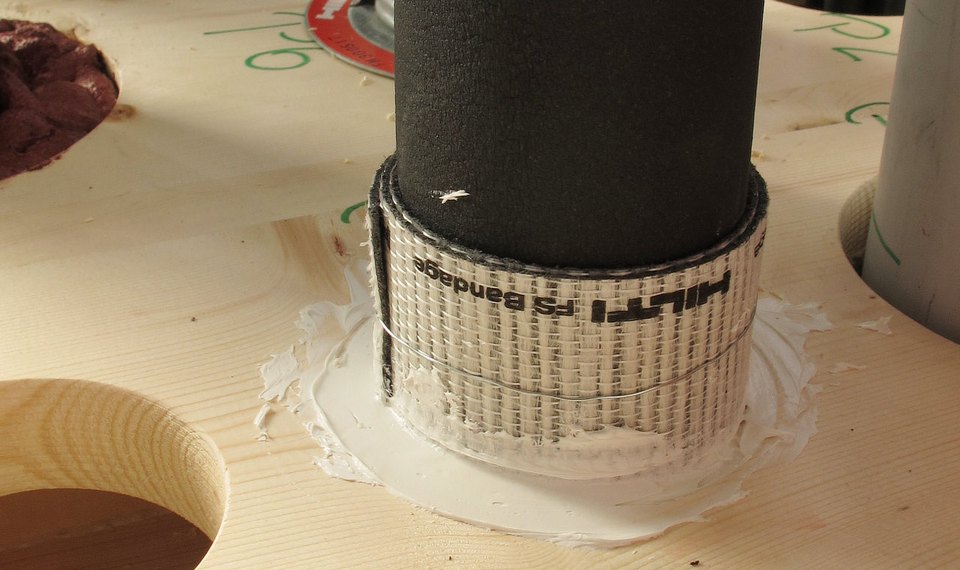

Lignatur and Hilti have successfully conducted fire resistance tests in accordance with the European standard EN 1366-3 (Fire resistance tests for service installations – Part 3: Penetration seals). The results are compiled in classification reports, technical assessments, and approval documents. This provides all planning stakeholders with the necessary documentation to implement multi-storey timber construction projects using LIGNATUR elements in a legally compliant and practical manner.

«Brandschutz im Holzbau» von Hilti mit LIGNATUR

GAS IBS Linz Feuerwiderstandsfähigkeit von Installationskanälen

Early Planning for Project Success

Practical experience and external studies (e.g. Lean Wood, TU Munich, Lucerne University of Applied Sciences) confirm the need for early-stage detailed planning in timber construction. Firestop planning suitable for timber construction requires both practical and cost-efficient solutions based on tested installation details and aligned with the timing of prefabrication processes.

Since penetration planning is implemented during the prefabrication phase, it depends on lead times for material procurement and production. It thus falls within the scope of execution planning and frequently overlaps with other planning and construction phases. Early coordination among all project stakeholders is therefore essential.

The cutting phase is a key link in the project timeline – it significantly impacts the coordination of subsequent trades, execution quality, and ultimately, the total project cost.

Exhaust systems

Measures to avoid the occurrence of fire through ignition of flammable elements with exhaust systems.

Construction example: installation shaft as a fire protection element for an exhaust system with negative pressure operation

1 connection pitched roof

2 connection flat roof

3 connection floor level

4 connection floor level above firing aggregate at connecting tube

5 connection floor level above firing aggregate

A external diameter exhaust system without fire resistance

B outer edge fire resistance element EI90

v external diameter connecting tube

x2 safety distance from outer edge of exposed exhaust system

The lower slat of the LIGNATUR element can reach up to the exhaust system if the distance demanded is x2 = 50 mm or less.

x3 safety distance from outer edge of exposed connecting tube with temperature class of exhaust system up to T400: x3 = 200 mm

a fire protection element AESTUVER, installation shaft AA EI90 (non-combustible) by Fermacell

b cavity insulation non-combustible

c constructive concrete ≥ 100 mm

d fire resistance board long-term heat resistant

d ≥ 18 mm (e.g. AESTUVER fire protection board d = 25 mm)

e firing aggregate