Installations

LIGNATUR offers the option to integrate installations in the element. The requirements for fire protection can easily be met by suitable measures.

Installation channel in LIGNATUR

We will be glad to make preparations for your installations on order.

We offer installation channels.

Cavity in LIGNATUR

The cavities of the LIGNATUR elements are sealed off at regular intervals with counterforts and cannot be used as installation channels without further measures. We will be glad to make preparations for your installations on order.

On request, we can remove the counterforts in individual cavities.

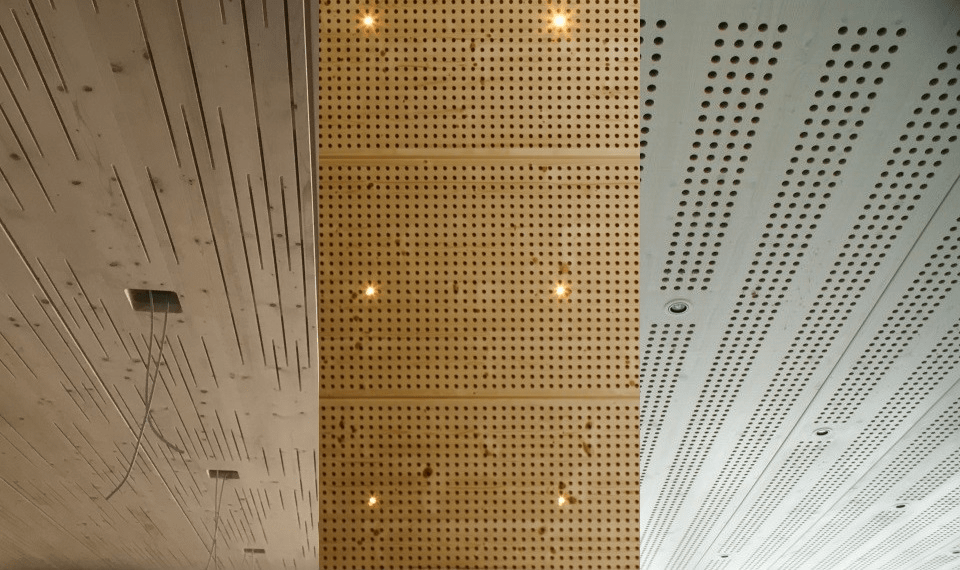

Cutting in LIGNATUR

Almost all luminaires may be mounted on normally flammable building materials such as wood (LIGNATUR). Luminaires that do not meet the requirements must be specially marked according to EN 60598-1:2008. No higher temperature may develop on any flammable surfaces that are thermally affected by the luminaires during normal operation. We therefore recommend using only luminaires with aluminium reflectors.

We mill grooves locally with the joinery machine.

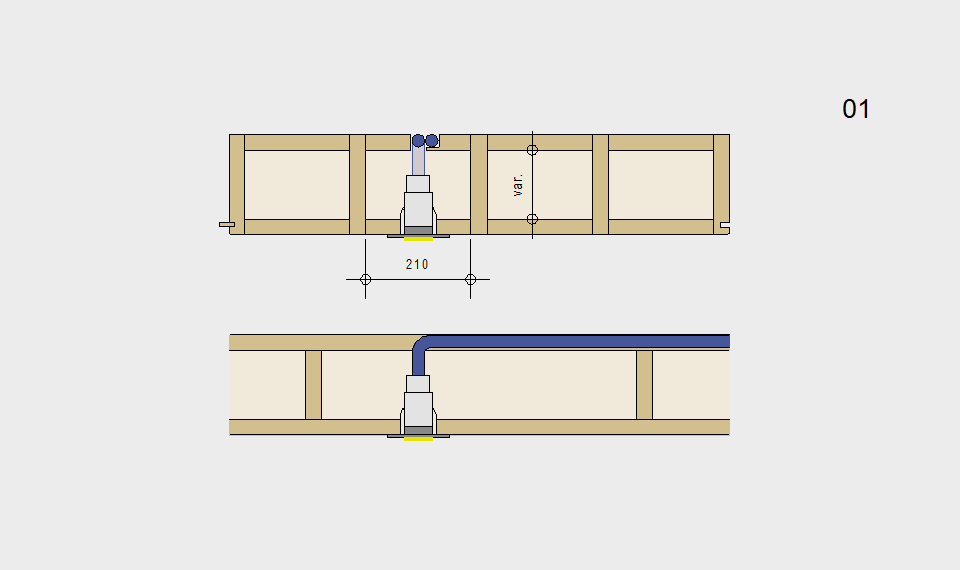

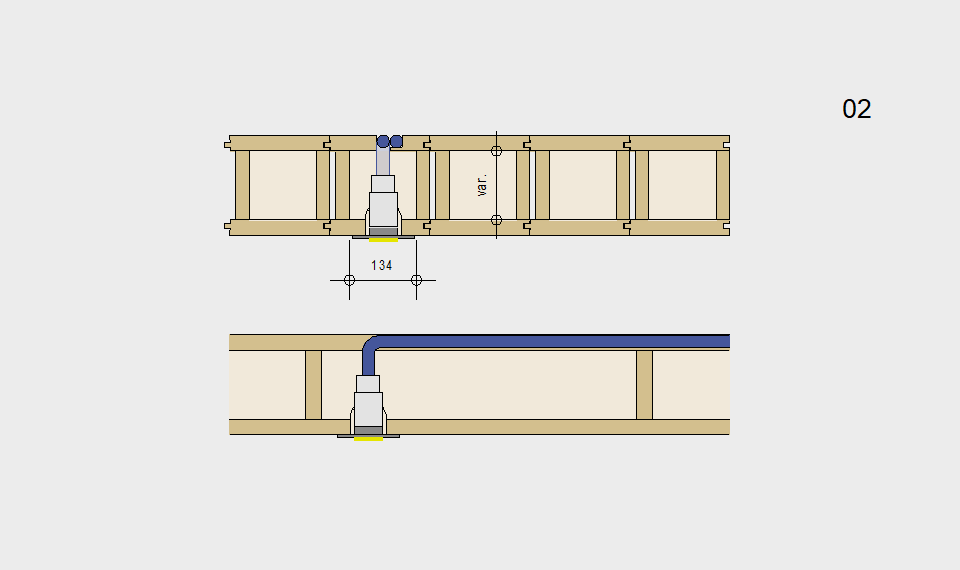

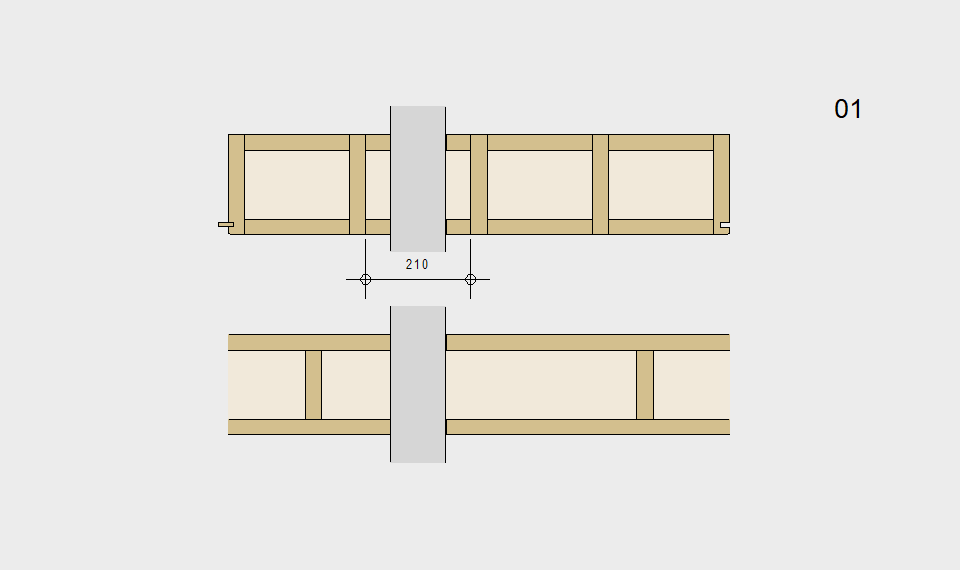

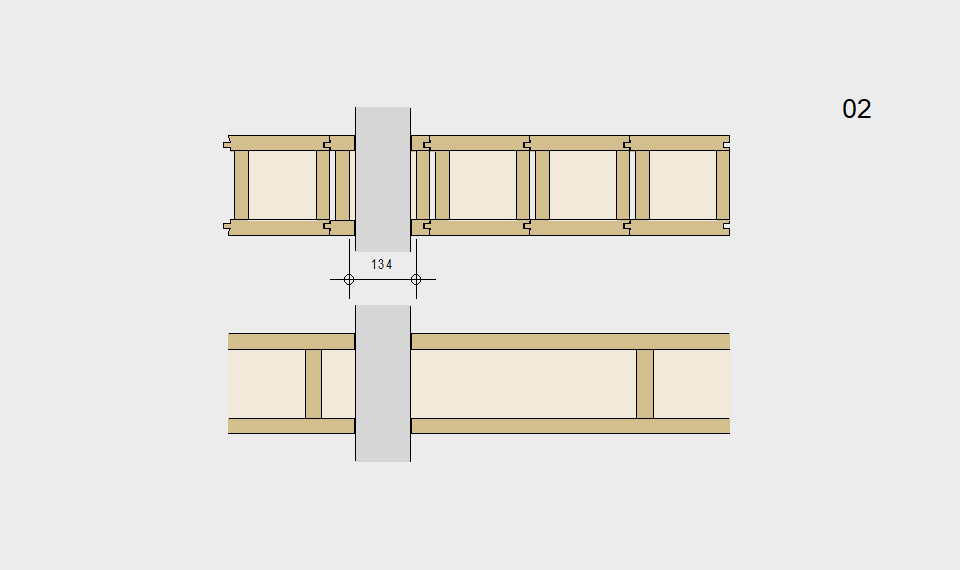

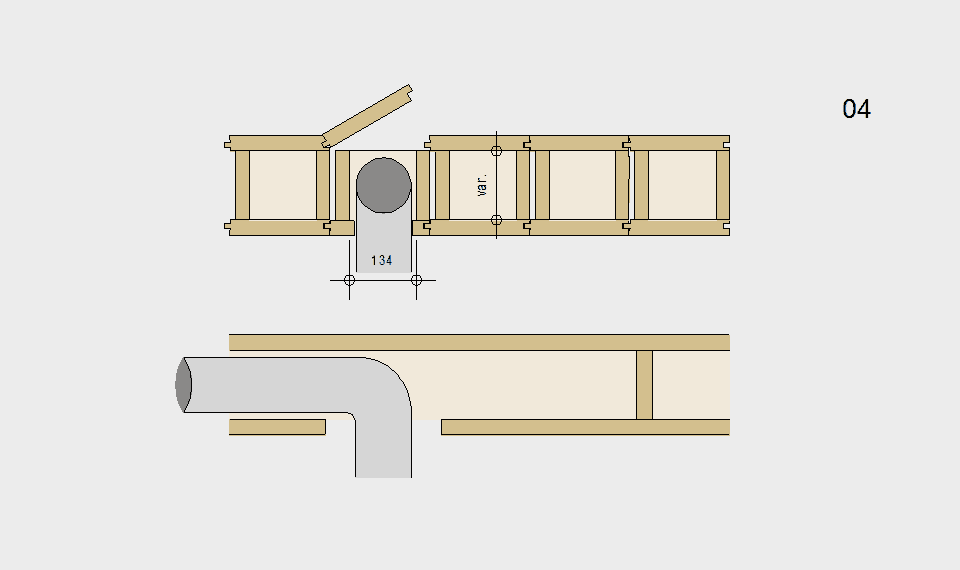

Vertical penetrations

Individual vertical penetrations are possible in the area of the hollow space up to 200 mm for surface elements LFE and 130 mm for box elements LKE without static reinforcement.

Requirements for installations are defined in the fire protection regulations. On the one hand, the integrity of the surface elements may not be compromised by suitable measures, while on the other the entry of fire into the component must be prevented over an adequate time period.

Partitions, exhaust gas systems

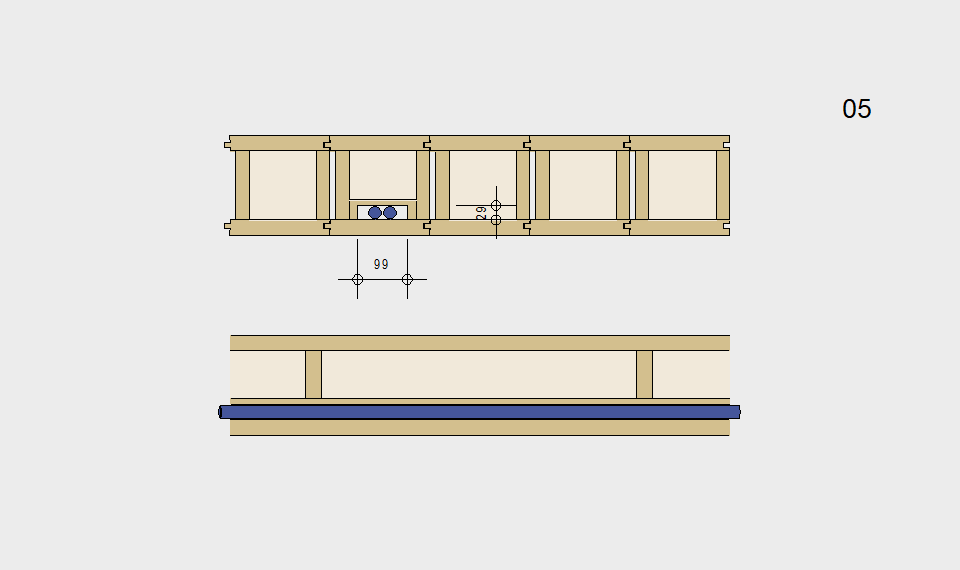

Ventilation ducts

LIGNATUR offers you possibilities to integrate ventilation ducts in the element.

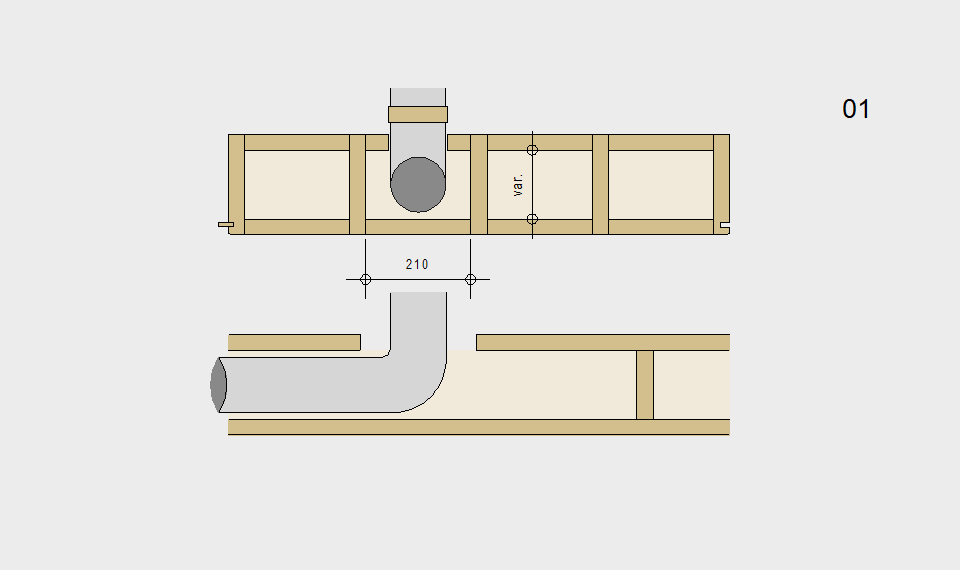

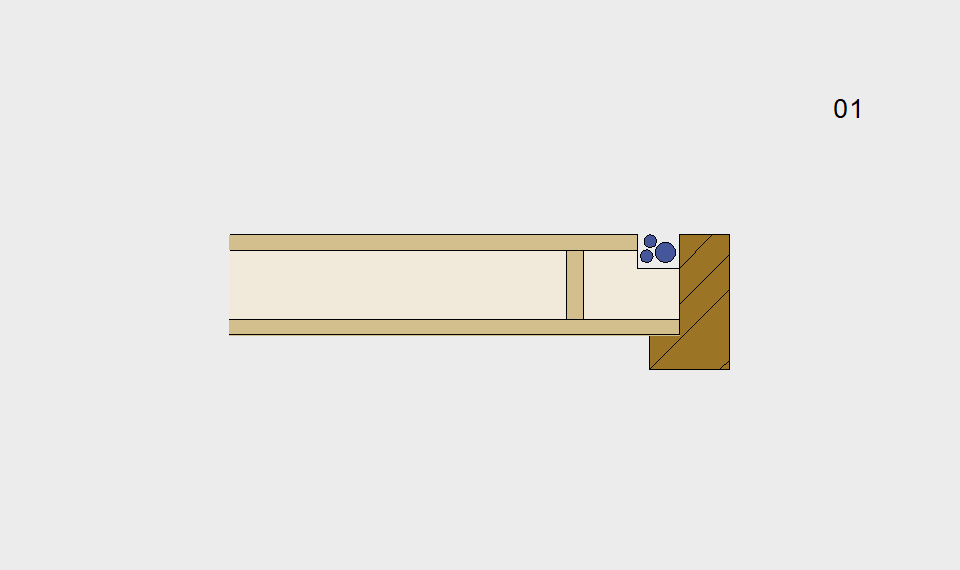

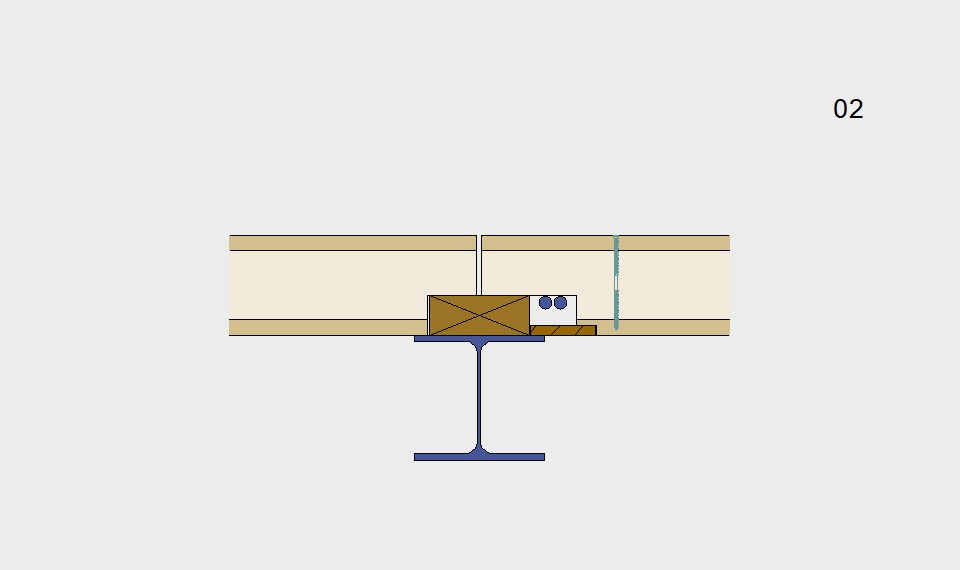

Lateral distribution on the support

Lateral distribution is easiest to do in the area of the support. The support statics must be checked for this.

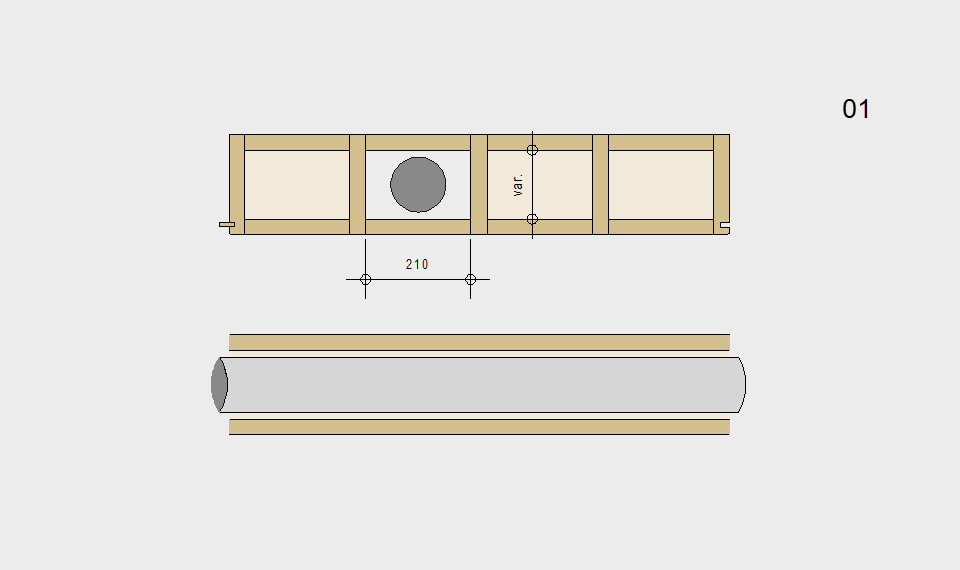

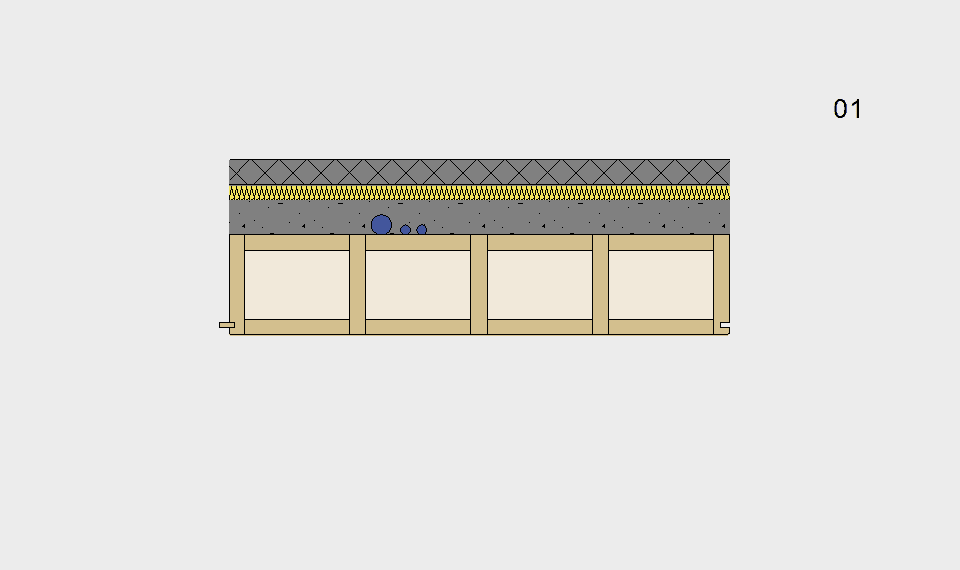

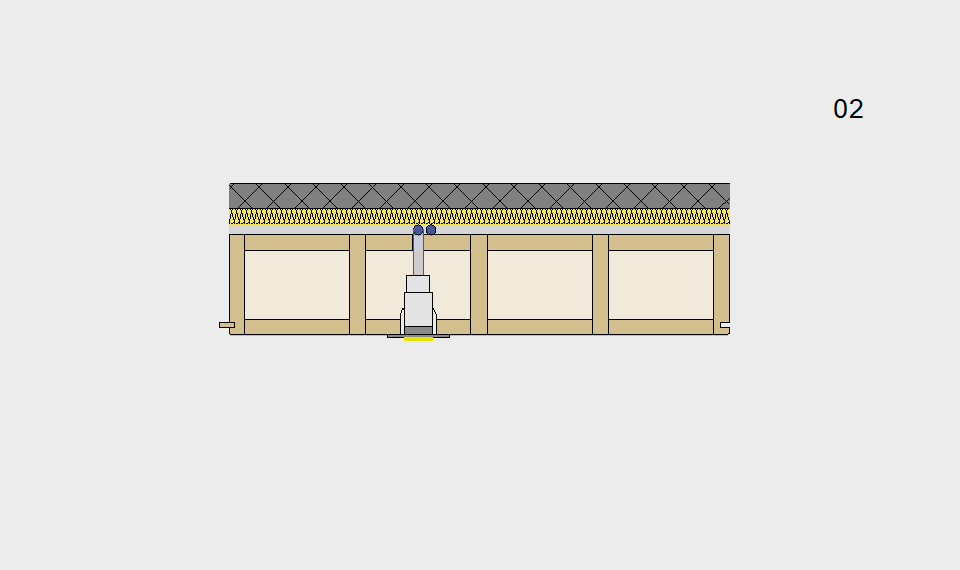

Distribution in the floor structure

Of course, the installation can also be carried out in the elastically bonded chippings (01) or in an additional impact sound insulation layer (02) and the floor heating can be laid in the screed.

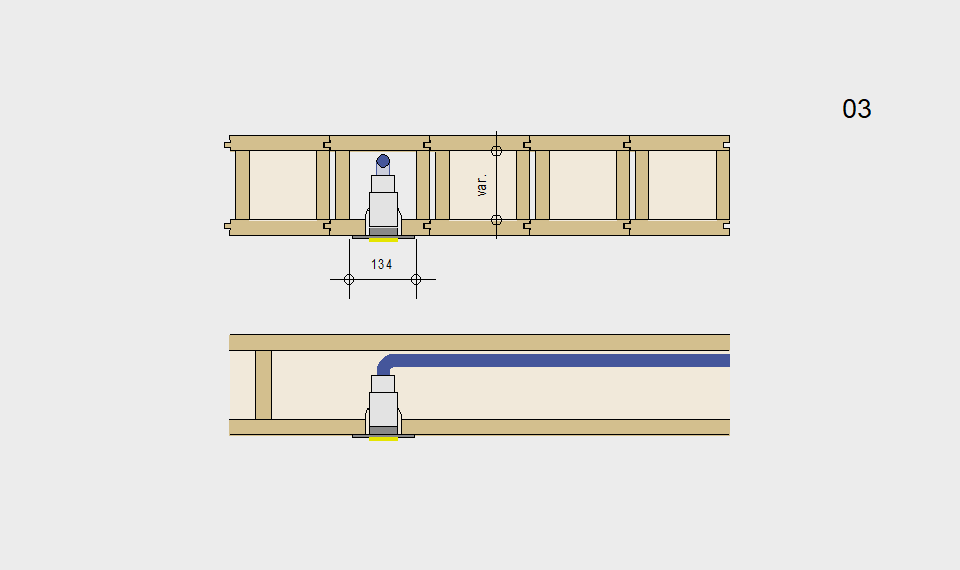

Assembly on the room side

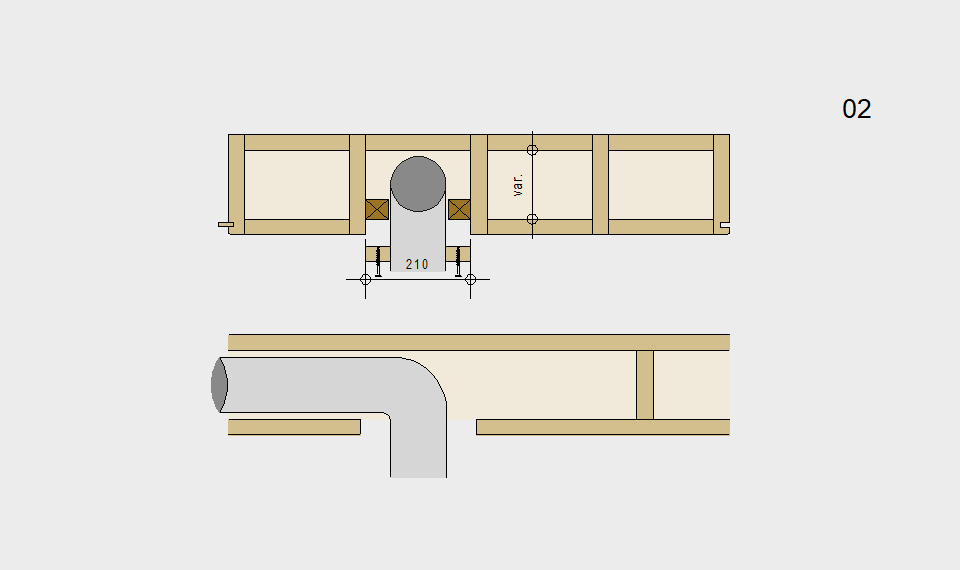

In case of assembly on the room side, the routing of cables in the LIGNATUR element prepared in the factory is done by hand. The cable can be pulled as required through the element and pulled out at the support with the aid of a hand hole. After installation, the wall is closed with panelling and the lights can be mounted.

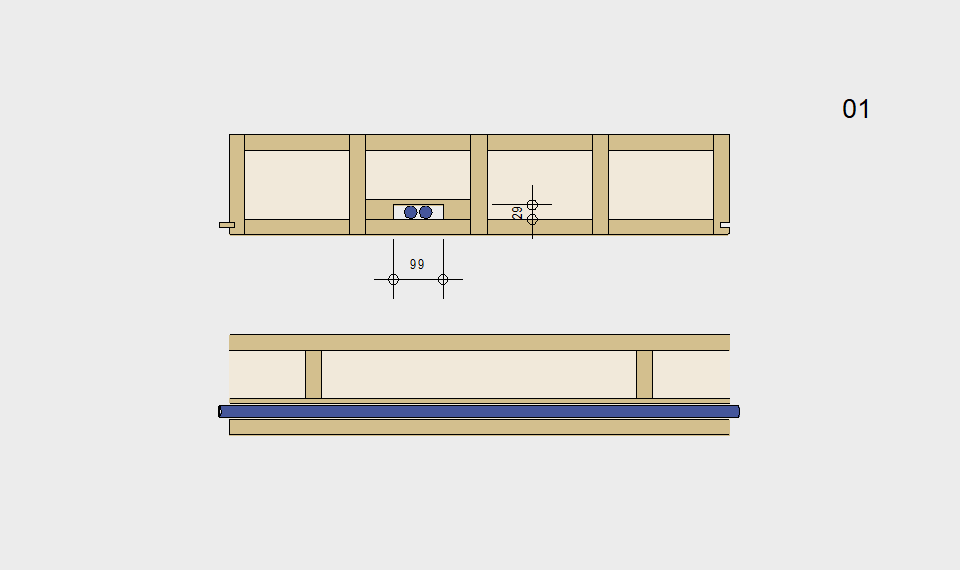

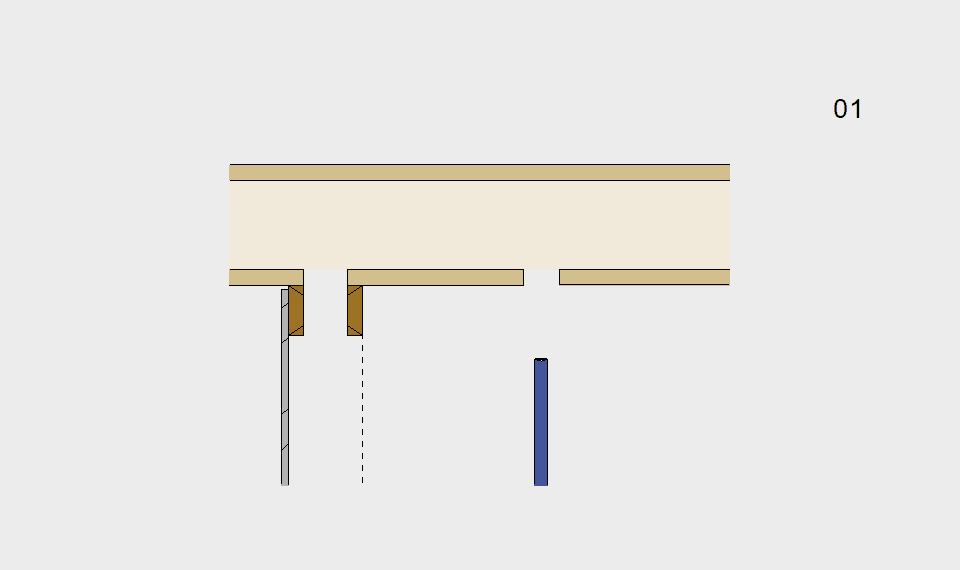

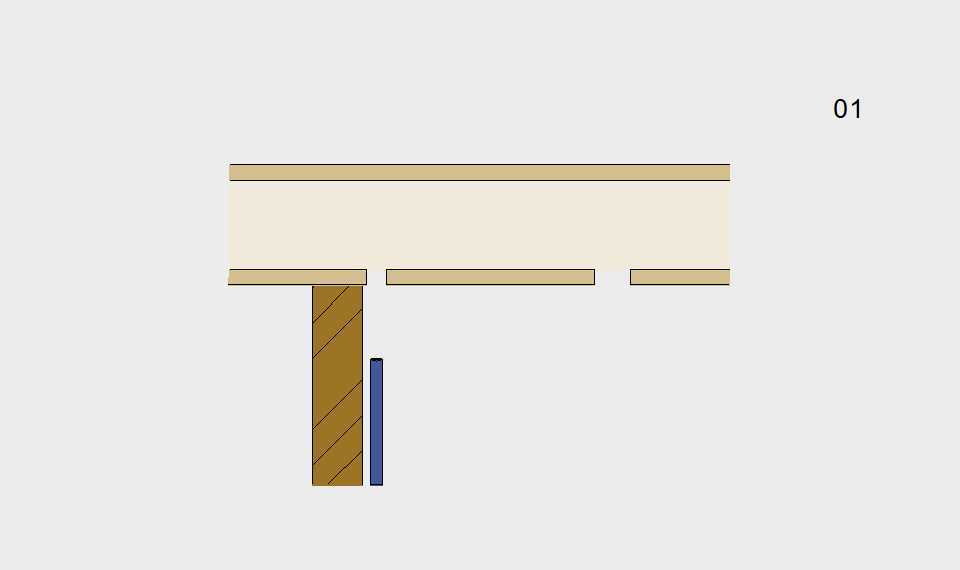

01 Ceiling prepared in the factory

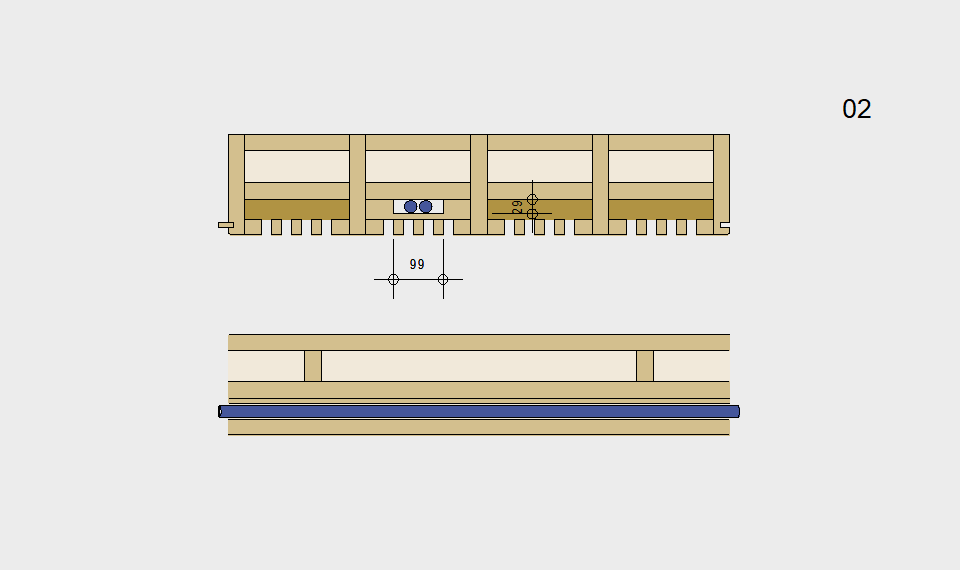

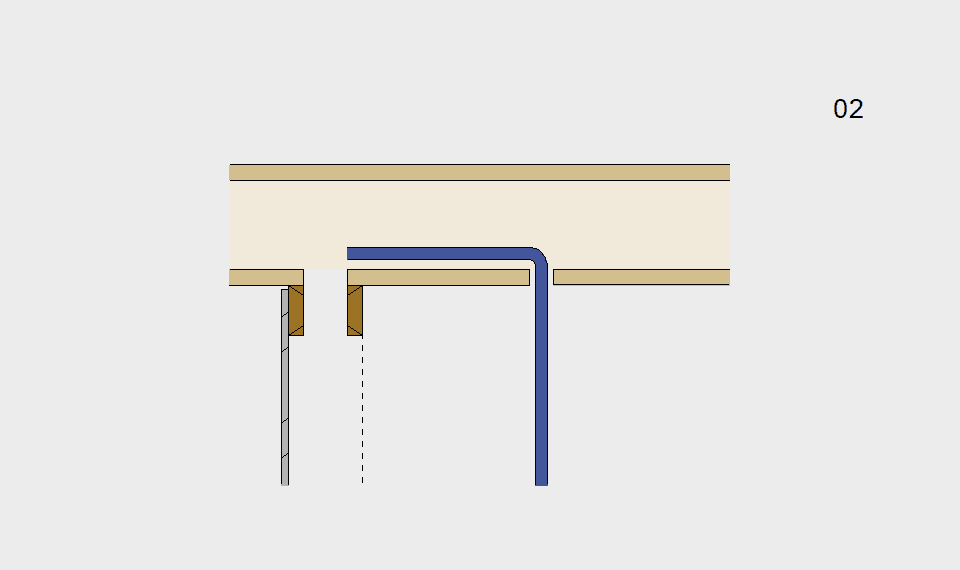

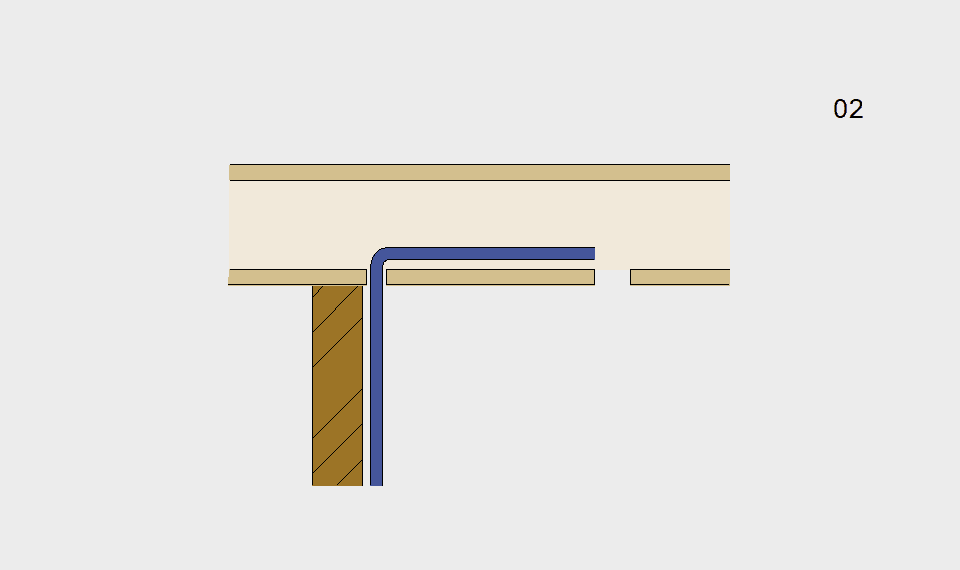

02 Insert conduit on the room side on site

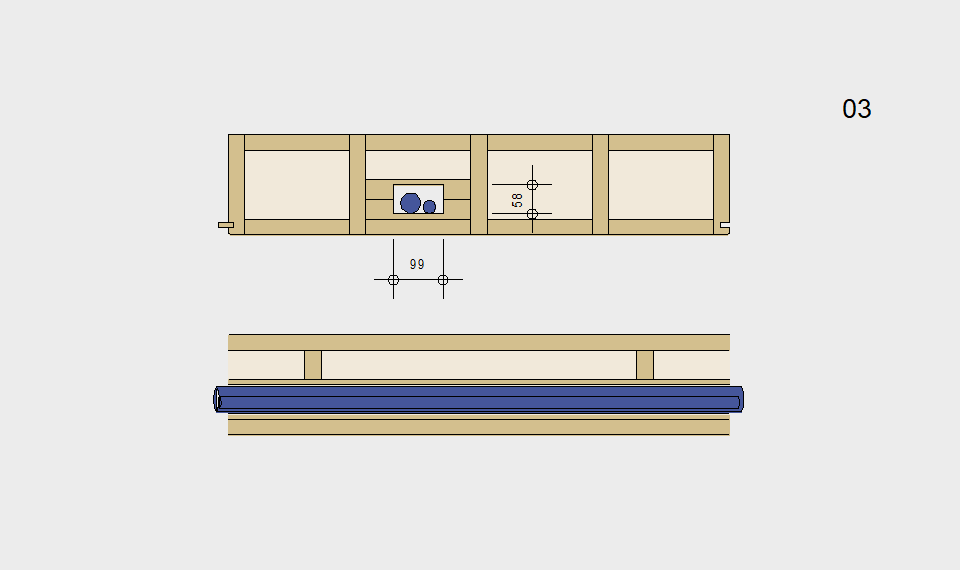

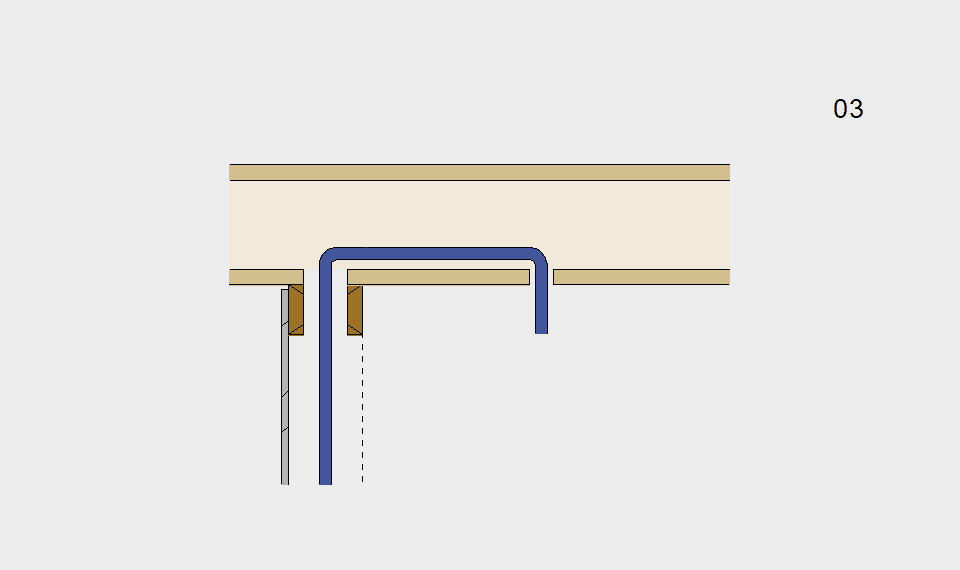

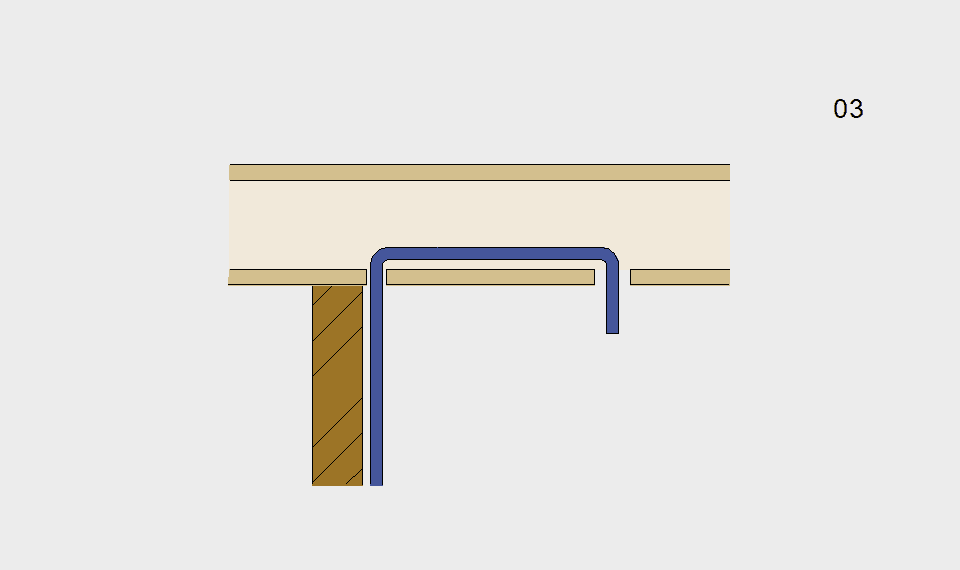

03 Pull the conduit out through the hand hole in the installation level

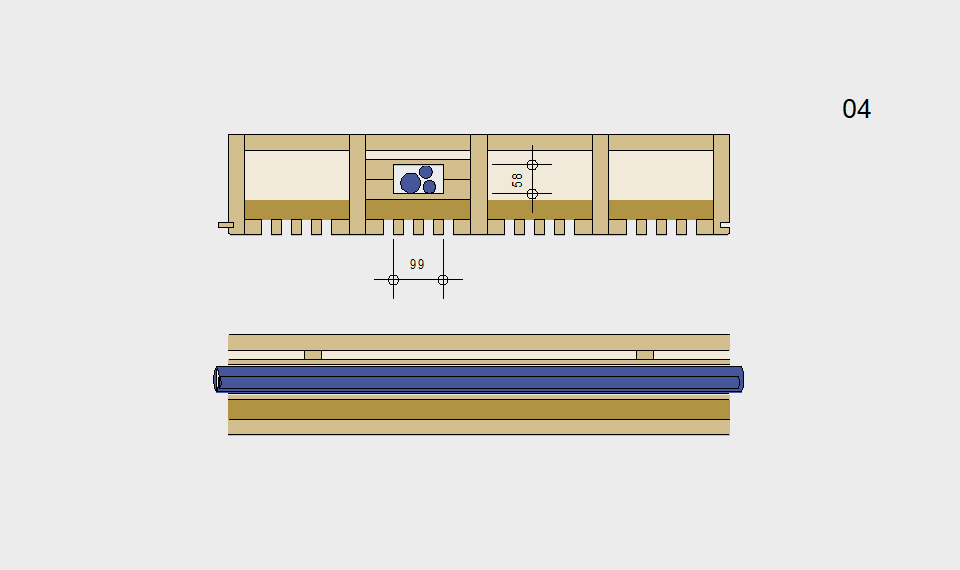

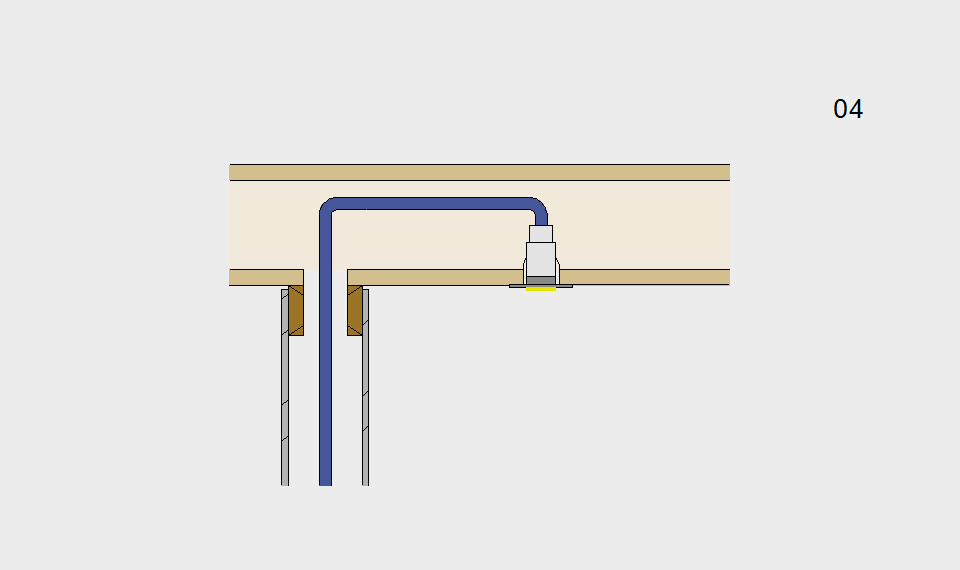

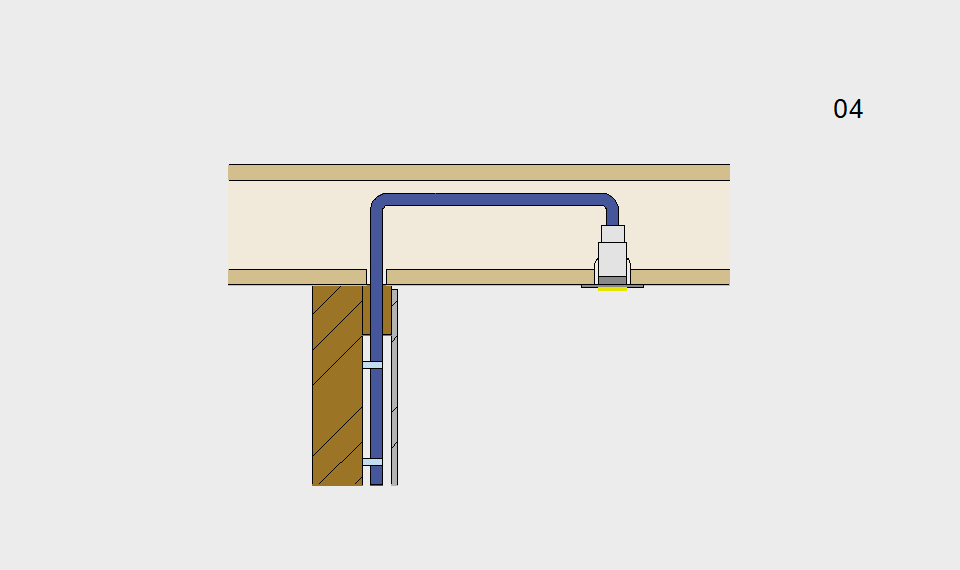

04 Completion of installations

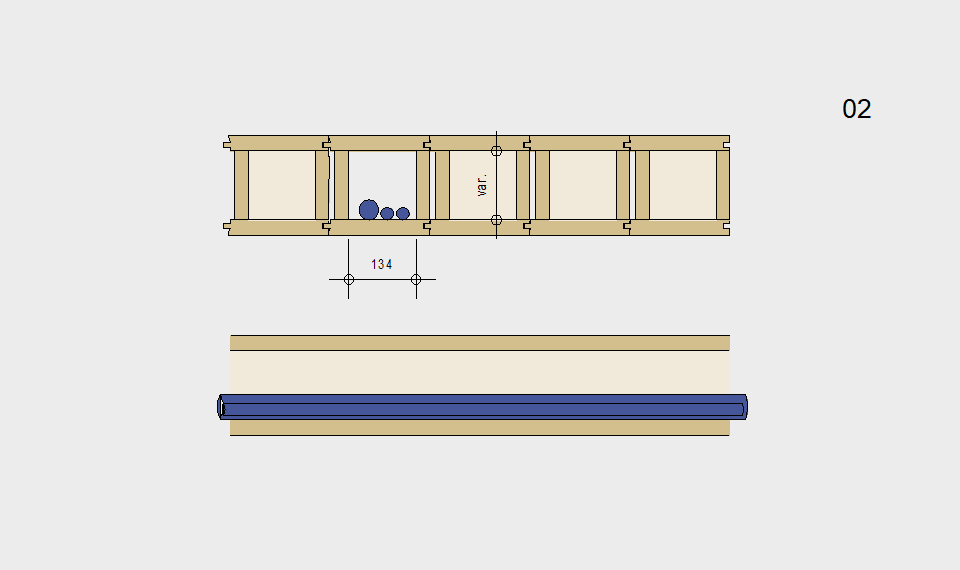

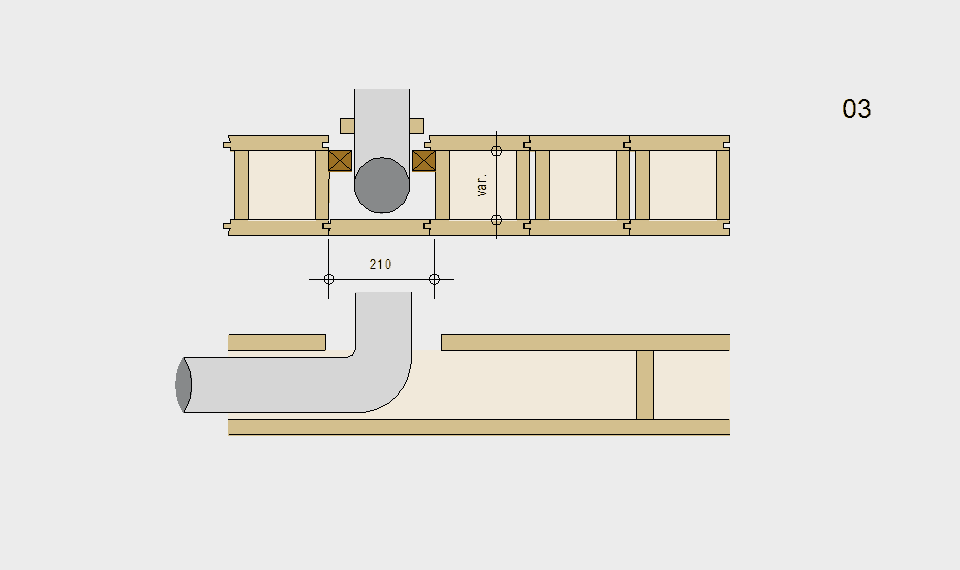

Assembly at installation level

In case of assembly in the area of the installation level, the routing of cables in the LIGNATUR element prepared in the factory is done by hand. The cable can be pulled as required through the element and pulled out in the room with the aid of a hand hole. After installation, the facing layer of the wall and the lights are mounted.

01 Ceiling prepared in the factory

02 Insert conduit on site

03 Pull the conduit out on the room side through the hand hole

04 Completion of installations